Laser Materials.

What materials can I cut and engrave?

CO2 lasers can work with a huge range of materials, some work better than others.

Below we have complied a little overview of materials we love to work with and others we recommend you avoid.

In general all laser cutting generates fumes and particulates hazardous to health, therefore good ventilation and extraction is of paramount importance.

FabMaterials

Best cutting and engraving experience

There are many materials that can be used for laser cutting. However, we recommend the following list of 'Fab'Materials as ideal for laser cutting as they, in our experience produce some of the nicest results.

All of the following templates were made with the standard FabCore set up.

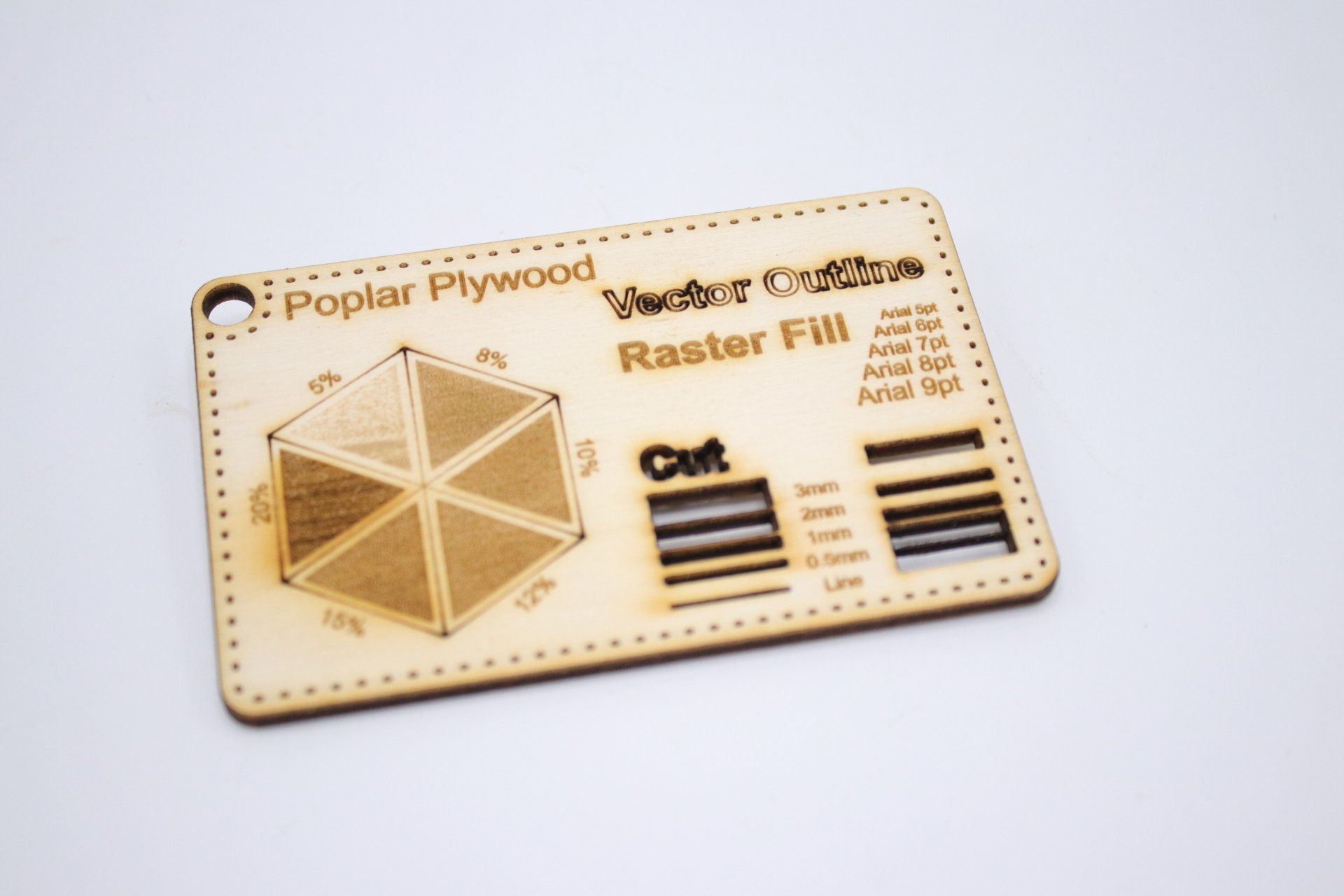

Poplar Plywood

Poplar Plywood is one of the most common materials used in laser cutting. Low cost and easy to cut, it is an ideal material to use in an educational setting.

However not all Poplar plywood is equal. To get the best laser cutting experience its best to look for high grade interior plywood; B/BB.

Birch

Plywood

Birch Plywood is a common material used in laser cutting. It is a harder plywood than poplar and can be used to produce more durable products. The harder nature also makes for cleaner and more contrasting engravings.

However not all Birch plywood is equal. To get the best laser cutting experience its best to look for high grade interior plywood; B/BB.

MDF (Medium Density Fibreboard)

MDF is a very popular laser cutting material because it cuts relatively well and is very cheap. However it is important to find the right kind of MDF.

Eco MDF or MDF with a low formaldehyde content grade E1 will cut the best. Construction MDF found in most hardware stores will often cut badly and create a large amount of smoke.

Felt (Polyester)

Felt is a great fabric to work with, often made of polyester it cuts very quickly and seals the edges to prevent fraying. It is available in a range of colours and thicknesses. It is also possible to get ECO felt made from recycled bottles and wool felt. Natural wool felt will cut with darkened edges and does not seal like polyester.

Kraft Plex

Kraftplex is comprised of a wood cellulose material formed under high pressure, it bonds together without the need for glue or other additives, making it a great ECO material. It cuts cleanly and is a strong and durable alternative to MDF.

Card Board

Easy and fast to cut, corrugated and general card products are a great material to use with laser cutters. When cutting thick corrugated card its important to pay special attention to any flames that may occur, especially within the card itself.

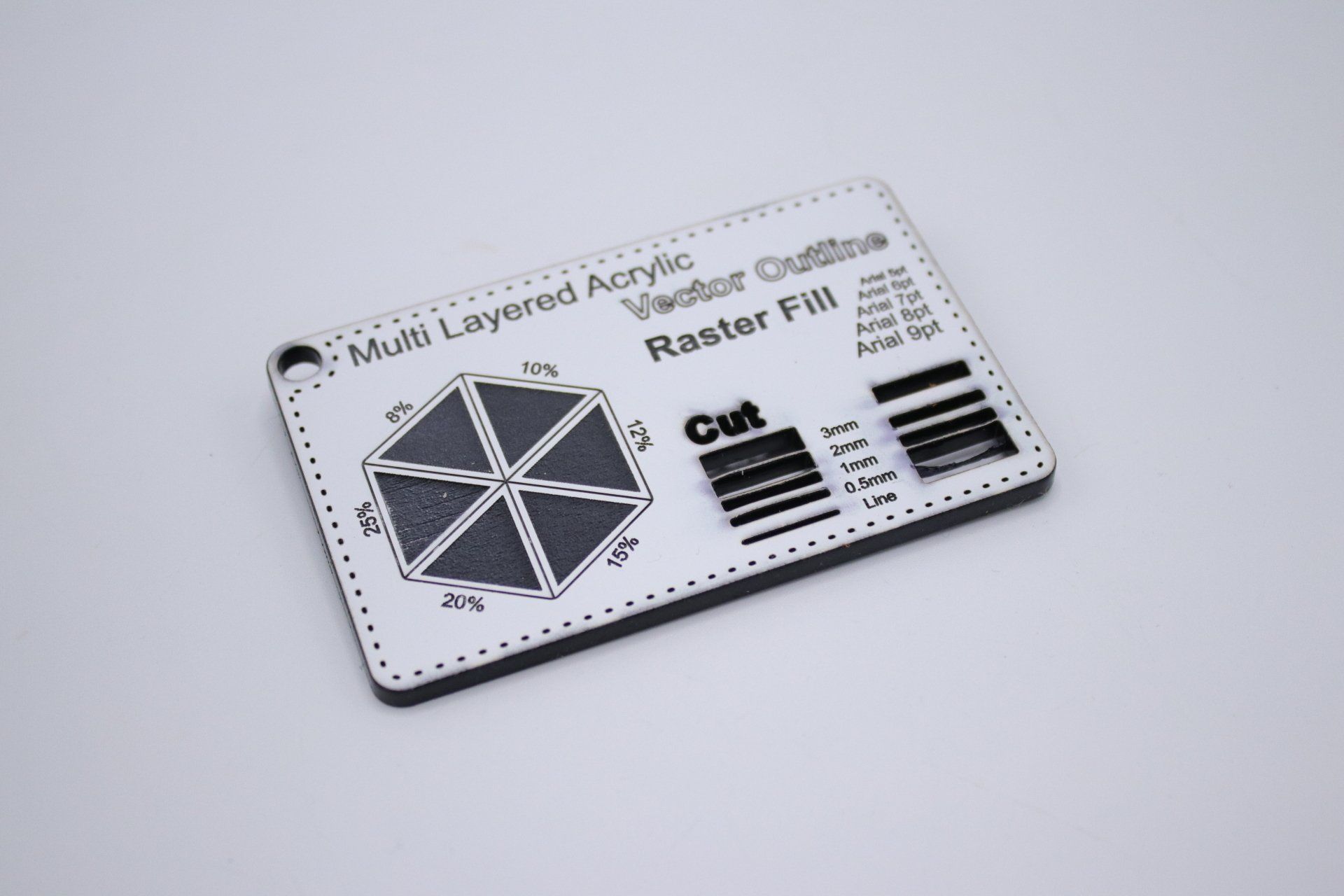

Acrylic (PMMA)

Acrylic comes in many colours, opacities and finishes. It also cuts very well, making it an ideal material for all sorts of laser cutting and engraving projects.

Polypropylene (PP)

Available in thin sheets 0.5-0.8mm polypropylene is a useful material for creating foldable products or as backing for fabric. It cuts relatively well but can leave a bit of a raised edge.

Polyethylene (PE)

When looking for a foam material Polyethylene works great. Available in many thicknesses and colours, it cuts much better than the alternatives and produces relatively little smoke and smell. Solid polyethylene sheets leave a raised cutting edge and molten engrave

Cotton Fabric

Cotton is a nice material to cut and engraves with a nice contrast. Easily cut out your patterns for sewing together.

Leather Natural

Leather is a great material for creating tags and other upholstery items, engraving nicely and cutting with relative ease. Use the perforation mode in LightBurn to create pierce holes to make stitching easy! Good ventilation is recommended as it can be quite smelly. Moistening the leather can help produce nicer cuts and reduce the smell.

Laser Acryl

Special dual layered acrylic allows you to engrave away the top layer to reveal the colour below. Great for sign making.

Laser Rubber

Laser stamp rubber is designed for making your own stamps. It products a large amount of smoke and dust while cutting and engraving which can be washed off easily once it is done.

Carton Paper

All paper/card products cut very well, you can also cut thicker honeycomb cardboard with relative ease. However take care as cardboard is particularly susceptible to fire.

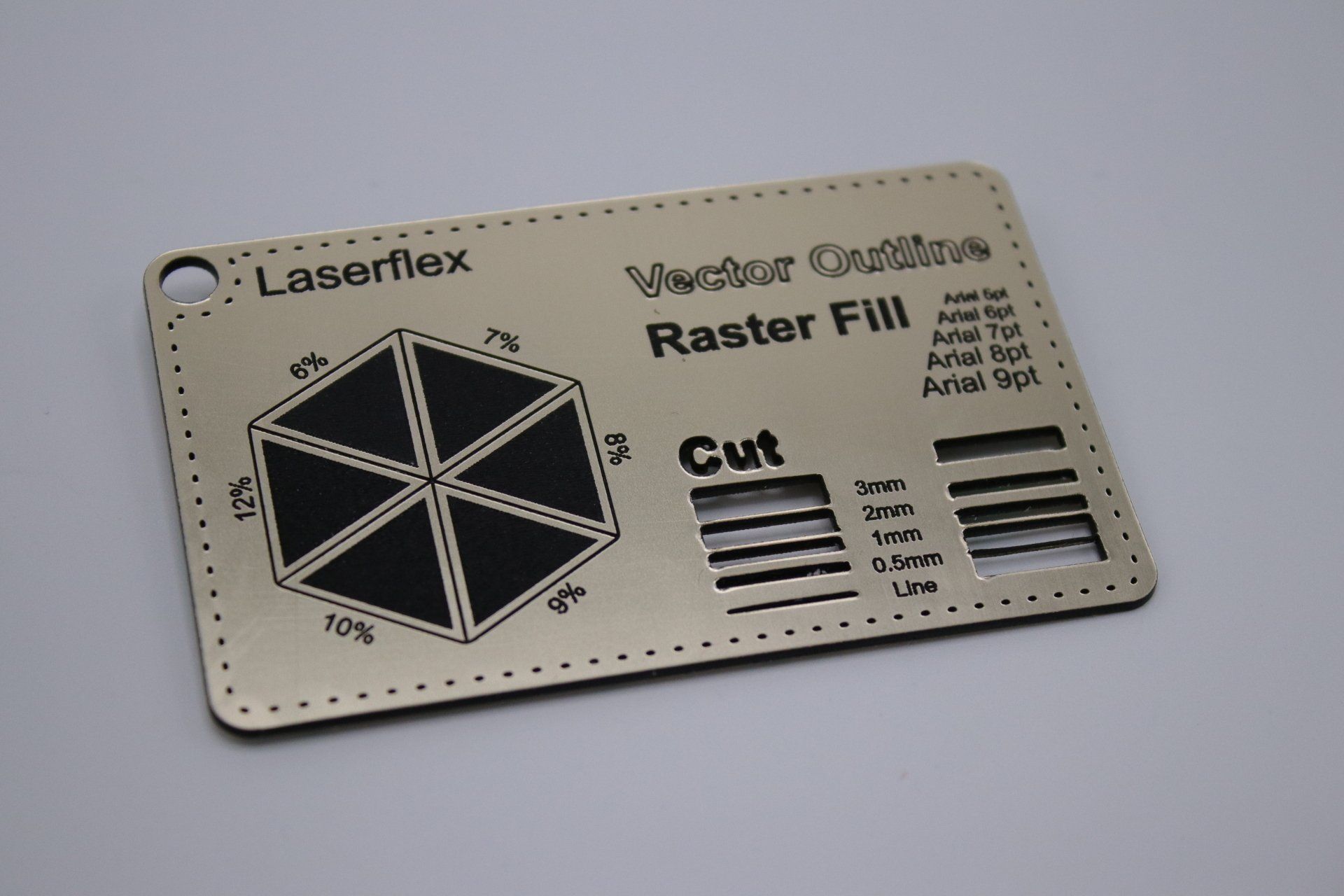

Laser Flex

Laserflex is an acrylic based material designed to look metallic on the surface. Underneath the metallic looking surface is a contrasting colour. This makes for some very nice sign making.

Cork Material

Whilst Cork cuts and engraves well it will often need cleaning up as it chars a lot. Engraving notice boards and coasters are nice projects to do with cork.

Hard Board

Hardboard cuts and cleans very nicely but it is a harder material to cut because of its high density. It also produces a lot of smoke when cutting, which will take its toll on your filters.

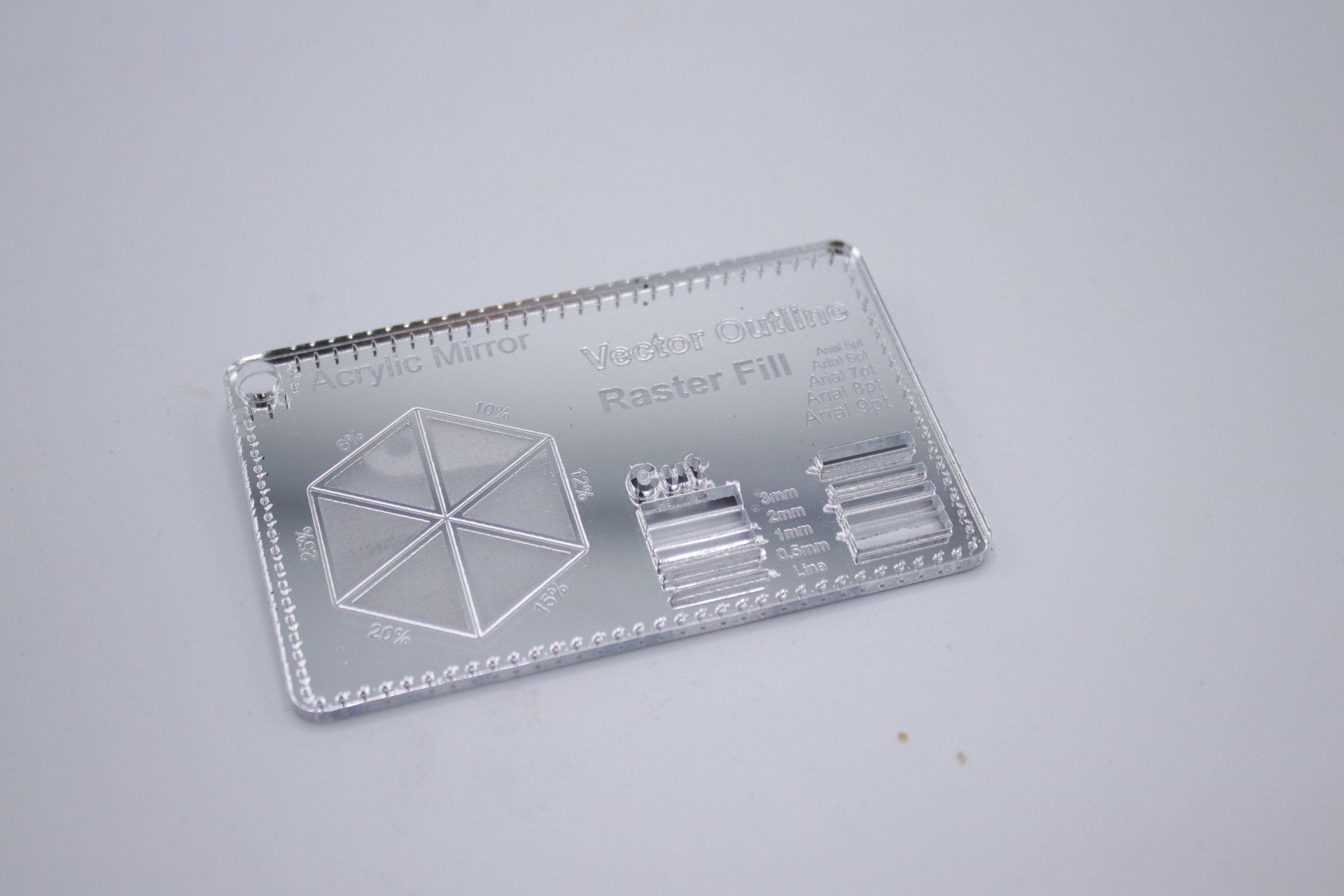

Acrylic Mirror

Clear acrylic backed with a reflective material. Etch away the reflective material from the back to create some cool mirror projects.

Fab'engrave'Materials

Engrave only materials

The following materials cannot be cut and can only be engraved.

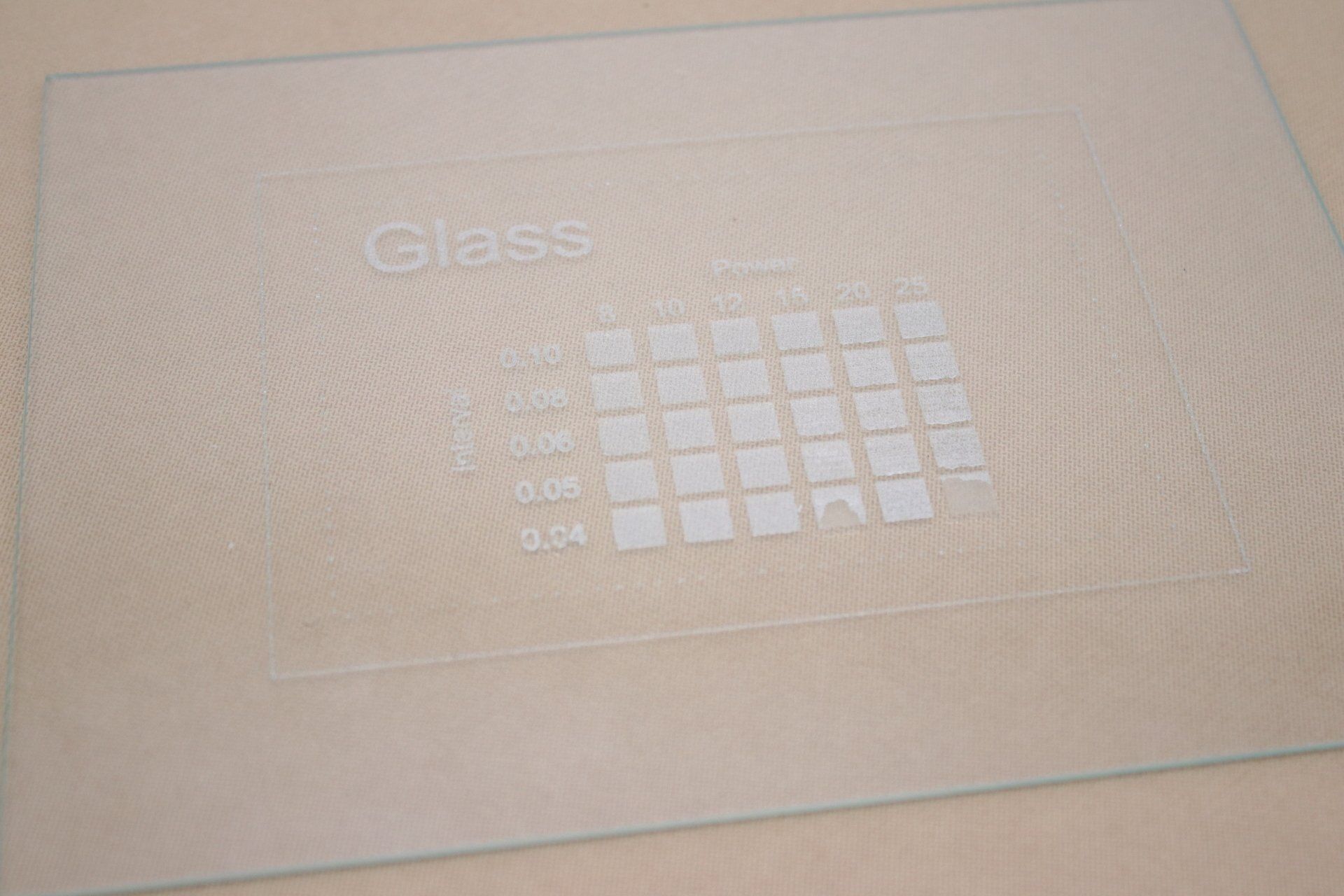

Glass Items

Glass makes for a great engraving material, especially for gifts; coffee/beer glasses. Take care to ensure you don't over heat the glass or it may shatter. A light coating of soapy water helps to prevent the glass from getting too hot.

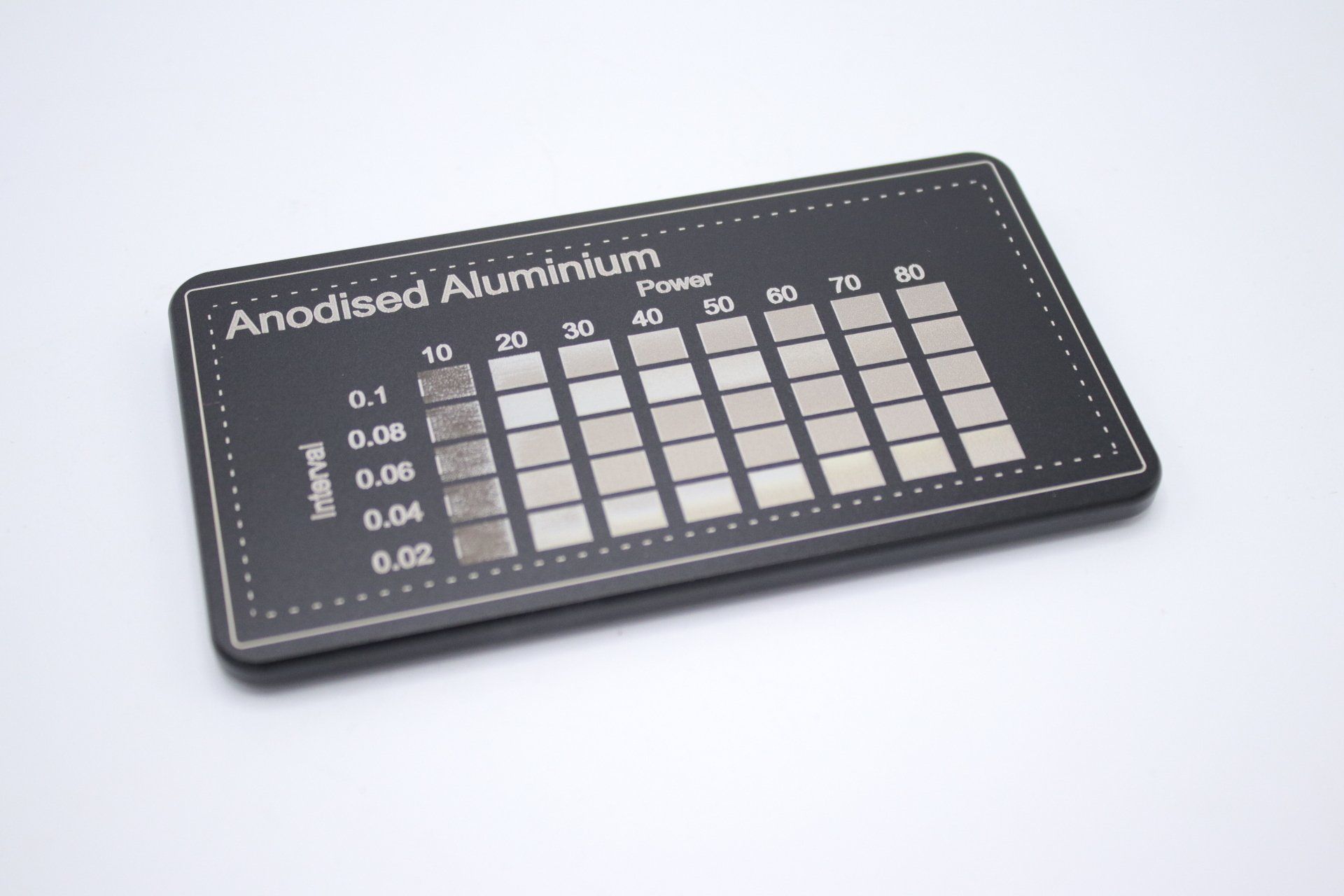

Anodised Aluminium

Anodised aluminium turns white when engraved at the right settings, allowing you to produce lovely markings.

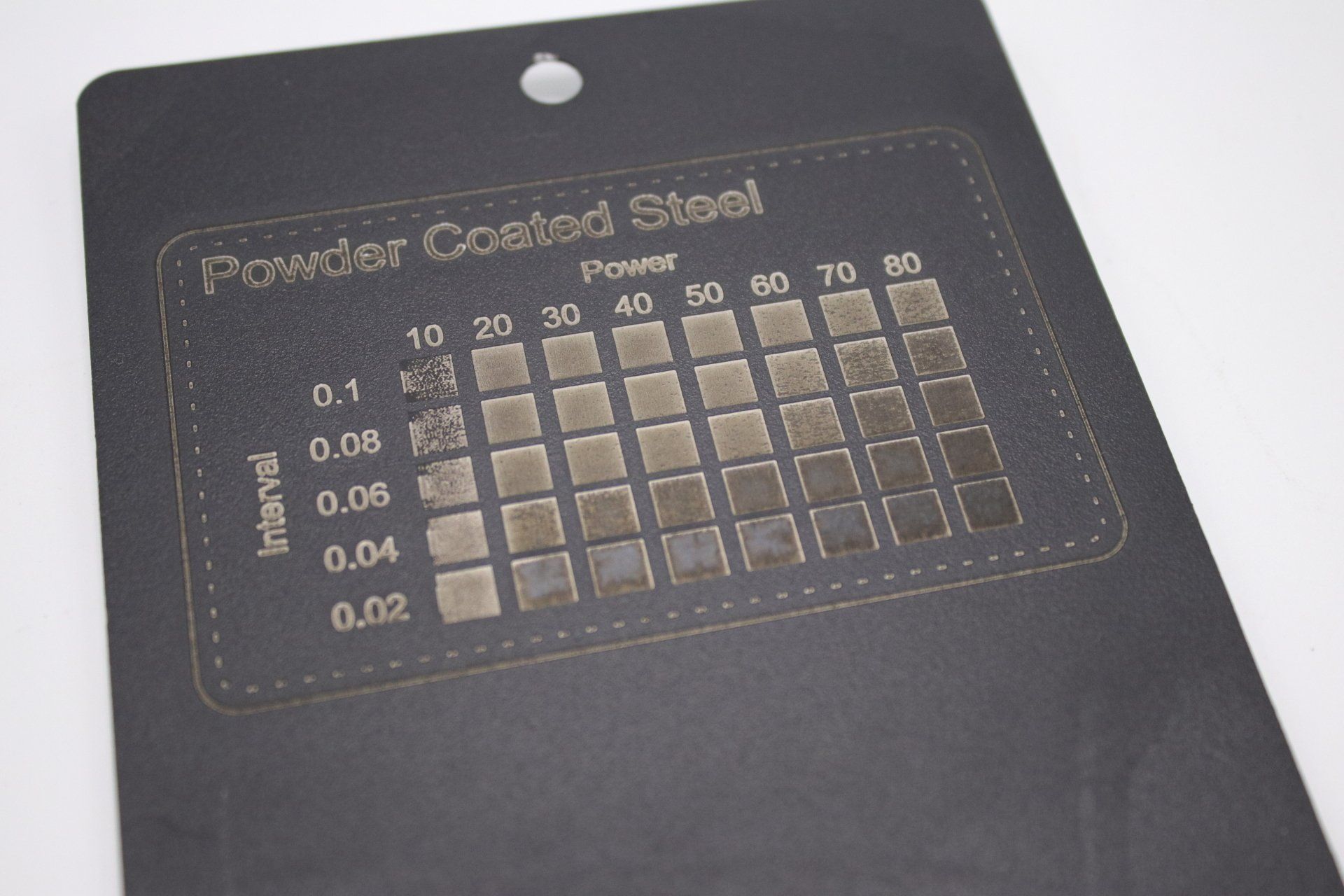

PowderCoated Metals

Metals which have been powder coated with polyester powder can be engraved by burning off the powder coat.

You can also use powder coat powder to make colour fill engraved jobs by using the laser to first engrave, fill and engrave again to melt the powder in place.

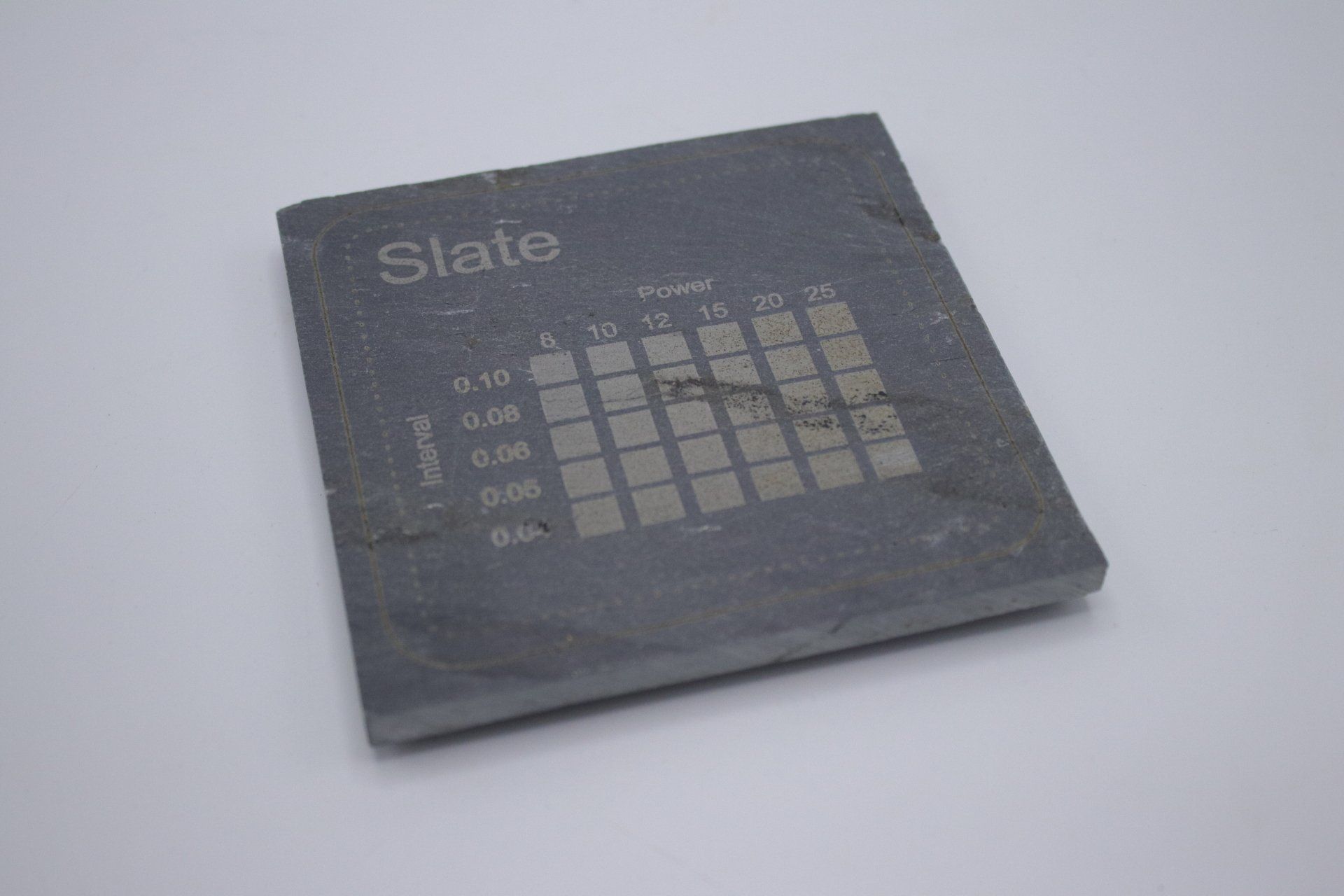

Slate / stones

Stones and slate are nice to engrave, normally turning white when you engrave them. Take care as too much power will often result in the stone or slate breaking.

Ceramic & glazed

Ceramics, like stones can be engraved. However, the markings are often not very clear. Painted or glazed ceramics often engrave to better effect.

'Notso'FabMaterials

Take great care when laser cutting and engraving.

The following materials can be laser cut and engraved. Some are very common and more typically used in industrial settings. However we recommend extra caution when working with these materials or to avoid them completely; especially in an educational environment. While lots of materials produce toxic gas the following materials are known to produce them at higher concentrations. With proper settings and extraction you can safely processes these materials. Improper handling and continuous exposure may prove hazardous to health.

POM Polyoxymethylene

If you need an engineering plastic POM is a great choice, laser cutting nicely, however formaldehyde and carbon monoxide are released during the cutting process. Does not produce good contrast for engraving.

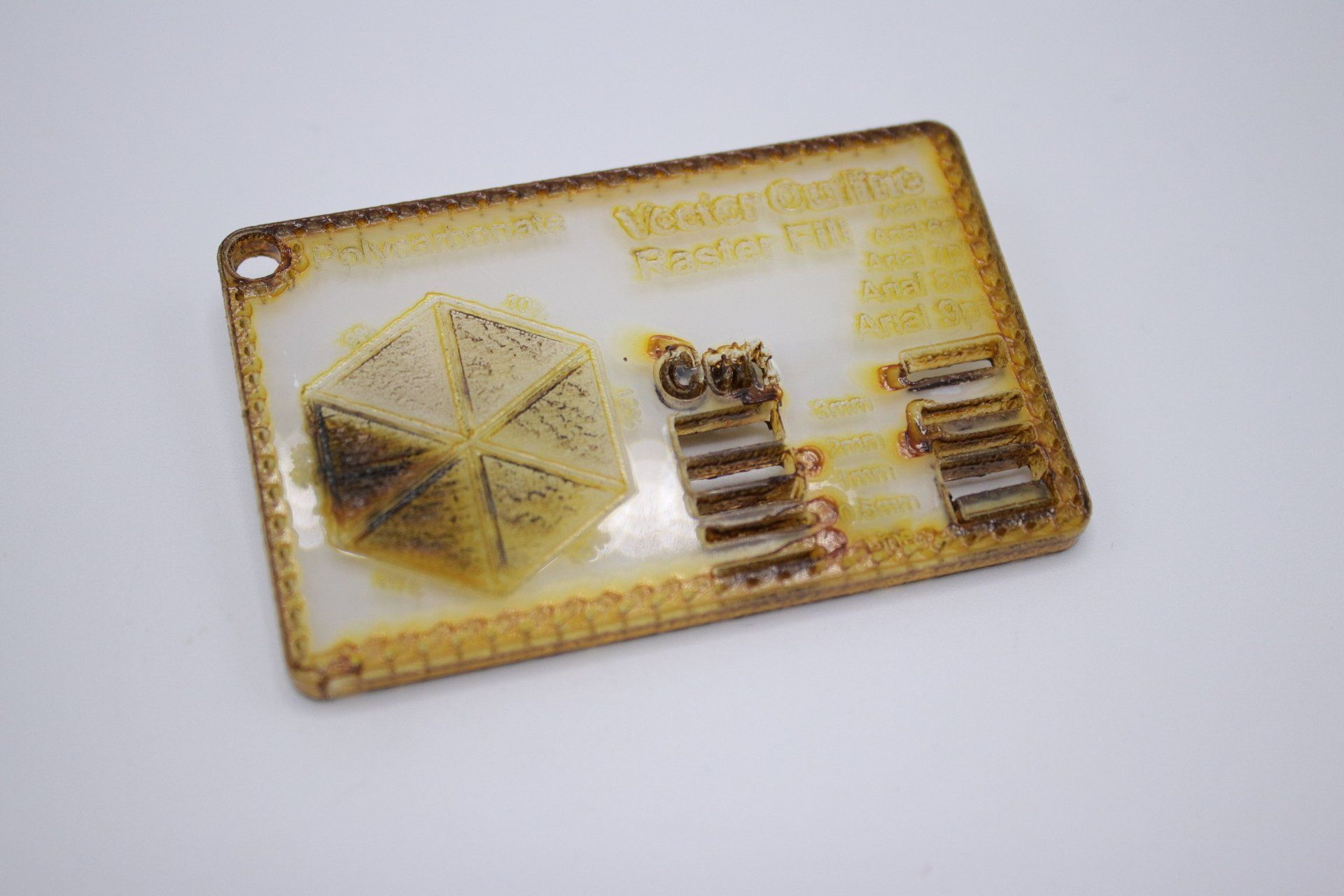

Polycarbonate (PC)

While not particularly dangerous to laser cut or engrave, it does not produce nice results and generates a lot of smoke and charring. Thin sheets may yield acceptable results.

Polyurethane (PUR/PU)

Polyurethane is a nice material in that it cuts and engraves well in both solid and foam form. Fake leather is often made with PU too. However take great care with your extraction as it releases Hydrogen Cyanide Gas when laser cut. Good extraction is a must. For this reason we prefer Polyethylene (PE)

ABS Acrylonitrile Butadiene Styrene

ABS tends to melt a lot and produces poor contrast when engraving, it also admits hydrogen cyanide gas so best to avoid it.

Polytetrafluoroethylene (PTFE)

Also known as teflon, this materials works well in thin sheets. Take care as it will generate carbonyl fluoride.

PolyStyrene (PS)

Polystyrene can be laser cut and produces good results. However watch out when cutting polystyrene foam as it can quickly lead to fire.

'Never'FabMaterials

Avoid laser cutting and engraving.

The following materials should be avoided.

PVC Polyvinyl chloride

PVC/vinyl (polyvinyl chloride) releases hydrogen chloride. This is extremely harmful to you and will severely damage your machine through rapid corrosion. Never cut PVC.

Alternative: PP (Polypropylene) PVC free vinyl

Epoxy Aliphatic resin

Not possible to laser cut or engrave, attempting to do so will result in a lot of toxic fumes; such as cyanide.

Also avoid composite materials such as Fiberglass, or carbonfiber sheets which have been coated with epoxy.

However Epoxy resins can be a great tool for making filled engraves and laser cut projects.

Food Things you plan on eating

While it is perfectly possible and safe to engrave foods you plan on eating, laser engraving on foods in a machine which has laser cut and engraved many materials of varying toxicity is a bad idea. It is best to avoid marking on food unless you have a machine dedicated to food safe grade production.