Always Safe.

FabCreator Laser cutters are

Class 1 Laser products.

Lasers are dangerous and eyes are precious, so it is of paramount important to ensure that your machine protects you from the direct and indirect laser radiation. A split second of direct or indirect laser beam radiation can be enough to permanently damage your vision. Your FabCreator machine to offer the maximum protection at all times.

What do these Classifications mean?

| Classification EN60825-1* | Description |

|---|---|

| Class 1 | Laser product is safe during all foreseeable use. Suitable for everyone; home, schools, fablabs, etc |

| Class 2 | Laser product may cause harm but is very low risk due to blink reflex. Do not deliberately stare into the beam for longer than 0.25seconds. Suitable for everyone; home, schools, fablabs, etc |

| Class 3R | Laser product is unsafe should you accidentally stare into the beam. Only suitable for businesses with specifically trained personnel. |

| Class 3B | Laser product is unsafe, high risk of permanent eye damage and burning of skin. Only suitable for businesses with specifically trained personnel with PPE. |

| Class 4 | Laser product is unsafe, high risk of permanent eye damage and burning of skin. Only suitable for businesses with specifically trained personnel with PPE. |

*Summarised from EN60825-1:2014, some classifications have been omitted due to irrelevance in regards to laser processing machines.

FabCreator Laser

Safety Features

There are many factors which go into making a safe laser cutter, here we will describe some of the most important ones we employ for our machines

Full Enclosure of the CO2 laser radiation

Made from a combination of aluminum, steel and polycarbonate our enclosures are designed to withstand the power of the laser and encapsulated safely inside.

Dual Channel Interlocks

Two door sensors provide a means to detect the door (enclosure) being open and closed.

Whilst open the laser should never fire.

Two channels of safety means that should one fail, the redundant channel will still perform the safety function.

Safety Controller

A Siemens or Pilz safety relay ensures the proper functioning of the interlock system. A start up test verifies every time the machine is started. Checking the interlocks were not defeated and that all the interlocks are functioning. Should a safety channel fail, the relay will prevent halt the machines operations, ensuring you are always safe.

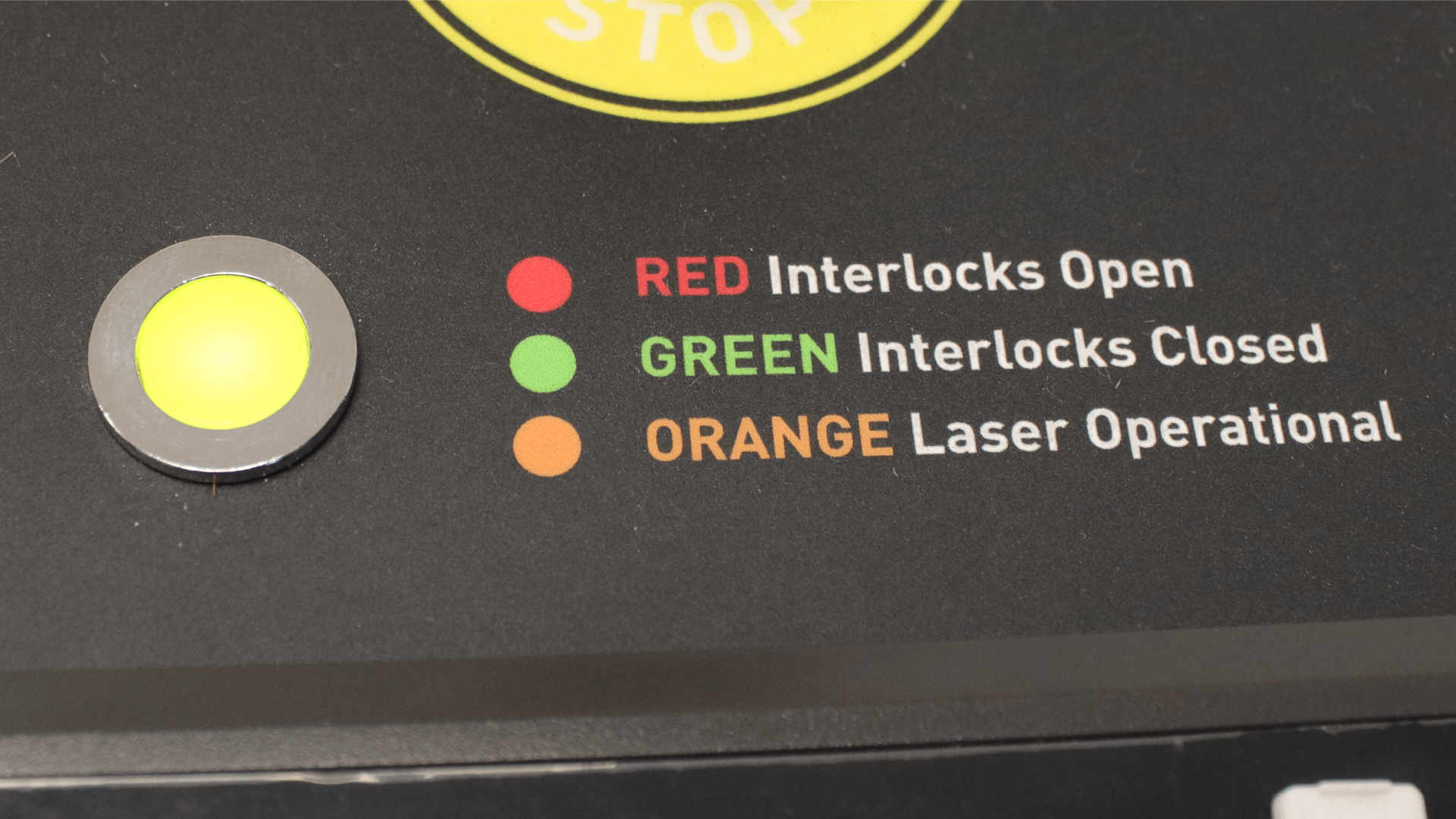

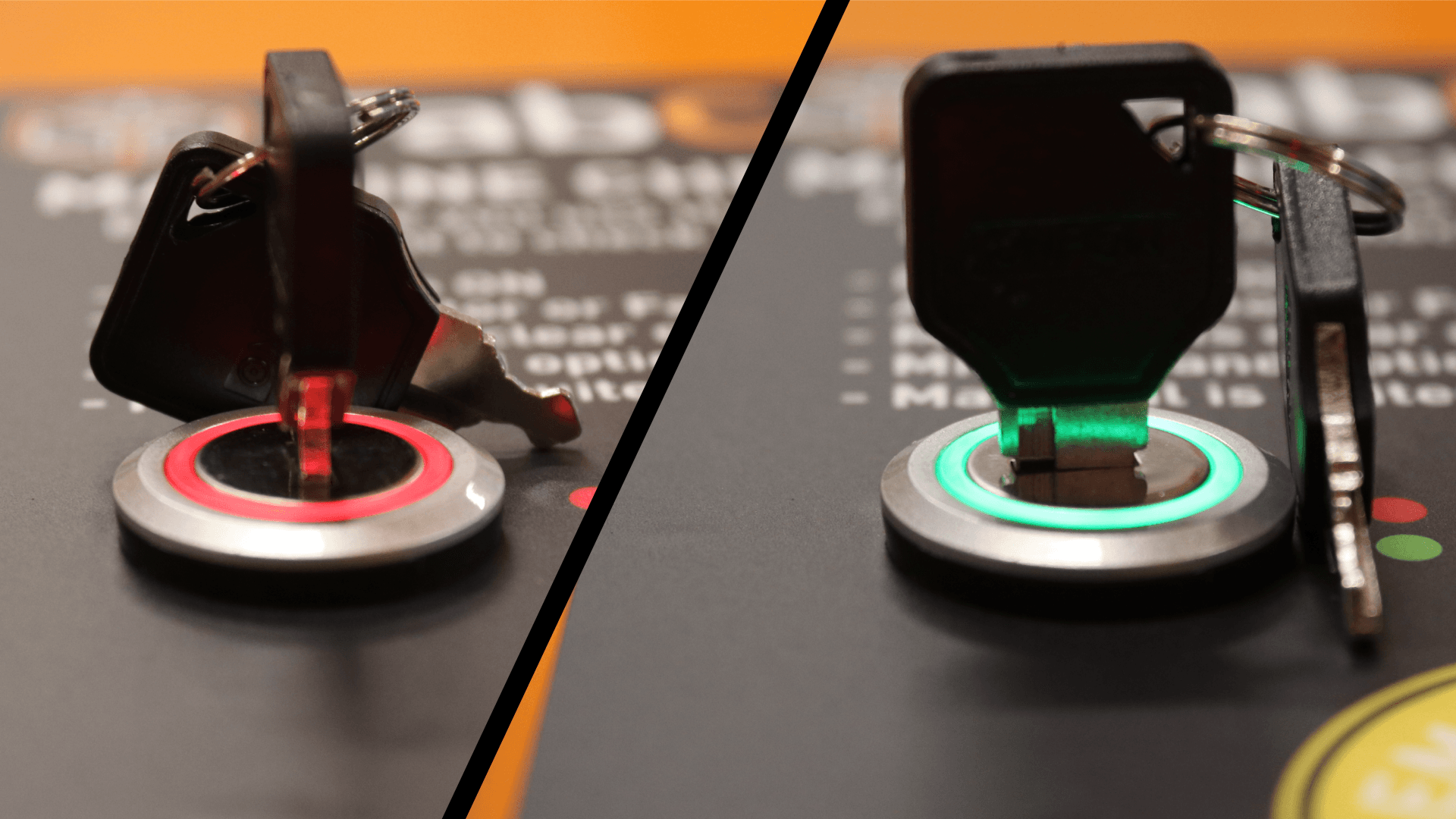

Laser Indicator

A tri colour LED provides real time feedback on the state of the interlocks and whether the laser is able to fire or is currently firing.

Emergency Stop

The Emergency stop provides a means to cut power to the entire machine almost instantaneously. Just in case of an emergency.

Informative Labels

Many informative labels are present to help guide users through the standard operating procedure and inform about the potential hazards.

Key Switch Control

A key switch provides control over power to the laser module. Ideal if you wish to control access to the machine at home, in an educational or public setting or in your business.

Optimised Air Flow

Smoke and particulates create a hazard to health. Our machines have a specially designed air flow to minimalise the build up of any smoke inside the machine, both with compressed air through the nozzle and an optimised air inlet and path for fume extraction. Compressed air also benefits the cutting process, helping to deliver cleaner cuts and engravings.

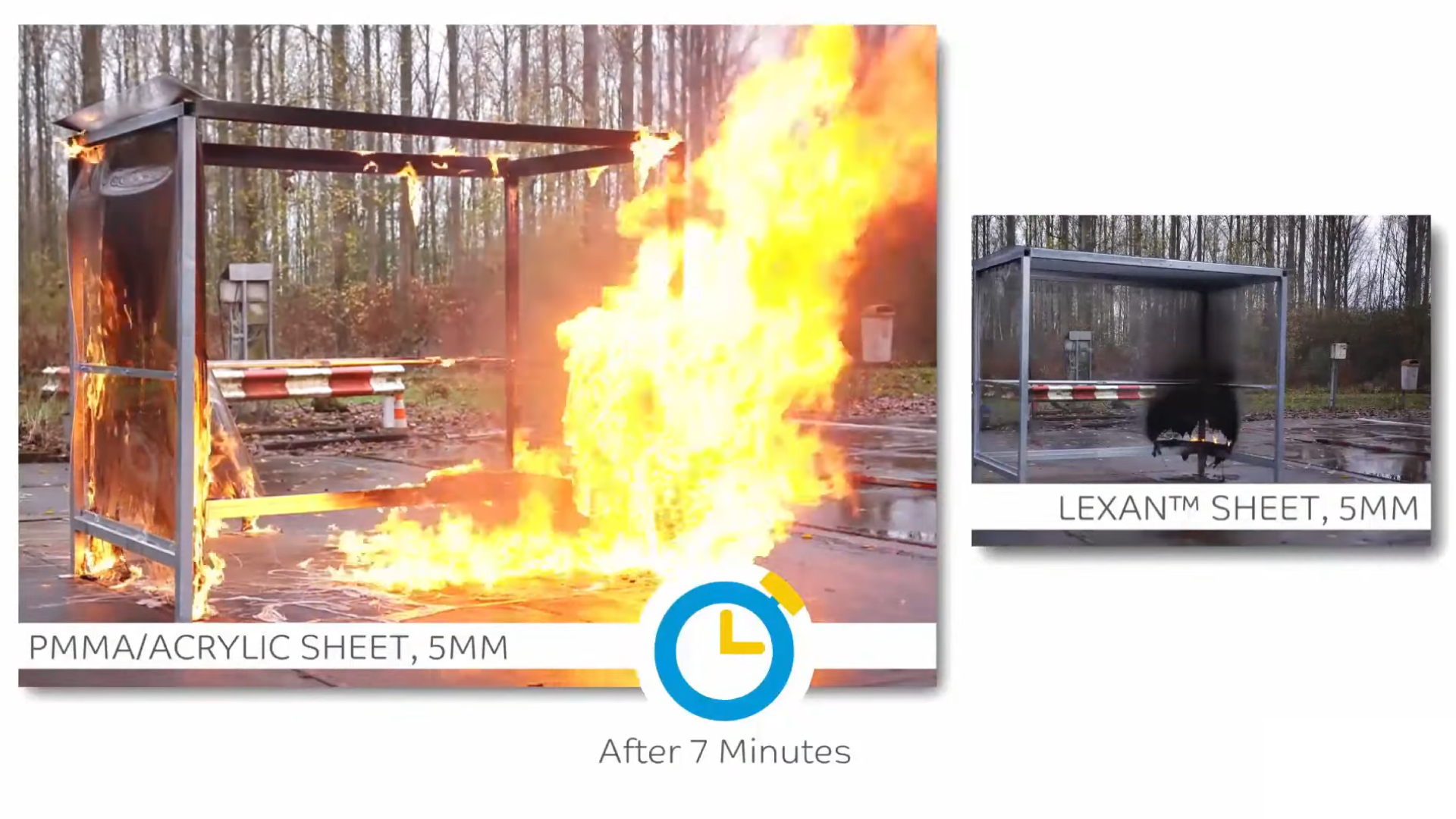

Fire Encapsulation

A thick fire retardant polycarbonate door aids in the encapsulation of a fire should the workpiece catch fire and the warning to never leave the machine unattended is ignored.

Here you can watch the

Original Video of a comparison between Acrylic vs Lexan (A brand of Polycarbonate)

Really Class 1?

How do I know a machine is really Class 1?

Sadly many companies advertise Class 1 security while unknowingly selling a class 4 laser product. This puts you and other potential users of the machine at high risk so it is important to know what is required for a laser to be considered Class 1.

We know it can be confusing to determine what is and what is not a Class 1 laser system. To help educate and protect people we decided to create a free non bias fact based and sourced resource

www.lasermachinesafety.eu

On this website you will find all the legal requirements laid out by European directives and harmonised standards.

4 quick questions to verify a Class 1 laser product.

We created a quick check list to help you verify if the machine you are considering is really a Class 1 laser.

01

EC-Declaration?

Can the company deliver a EC-declaration with the appropriate standards.

02

Do you need to access the laser?

A true Class 1 laser will never expose you to the laser when energised. This includes maintenance. It must not be possible to fire the laser whilst any access or maintenance panels are open.

03

Dual channel interlocks?

One door sensor/interlock is never safe for a laser cutter. Two interlock channels are required to ensure the laser will not operate if a singular sensor fails.

04

Are there warning stickers?

Inside every laser cutter designed for cutting materials will be a Class 4 laser. Should you remove panels, defeat interlocks or have a catastrophic failure you will be exposed to Class 4 laser radiation and therefore it is important your machine has warning labels to this affect.

*This is not an exhaustive list, but a good indicator the machine you are considering is indeed a Class 1 laser product.